Main Application types

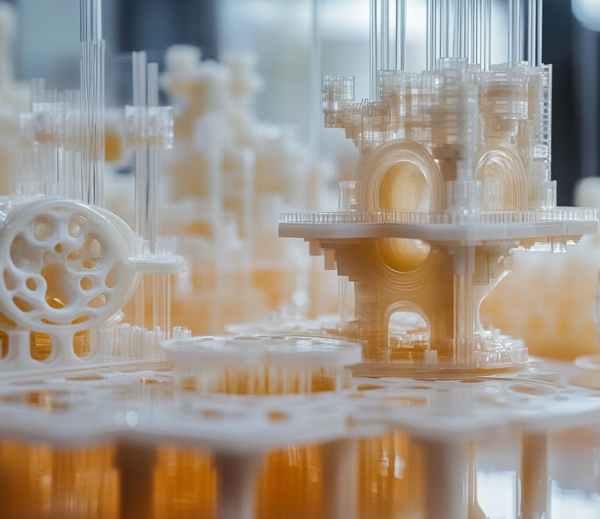

Mold cleaning machine: mainly used for cleaning the surface of injection molds, mold cores, and accessories of dirt, oil stains, rust removal, sulfides, plastic carbon deposits, and removing gas and other residues from the leather surface.

Dry ice cleaning machine: Using dry ice particles (solid carbon dioxide) as a medium, high-speed dry ice particles are sprayed onto the surface of dirt, and the physical reaction of temperature difference is used to quickly peel off the dirt. At the same time, there is no residue after dry ice sublimation, which will not cause secondary pollution.

Waterway cleaning machine: usually involves high-pressure water jet cleaning, pulse cleaning and other methods. High pressure water jet cleaning uses high-pressure water flow to impact the dirt inside the mold waterway and flush it clean; Pulse cleaning generates strong impact force through pulsed water flow or air pressure fluctuations to remove stubborn dirt.

Dry ice cleaning machine: Using dry ice particles (solid carbon dioxide) as a medium, high-speed dry ice particles are sprayed onto the surface of dirt, and the physical reaction of temperature difference is used to quickly peel off the dirt. At the same time, there is no residue after dry ice sublimation, which will not cause secondary pollution.

Waterway cleaning machine: usually involves high-pressure water jet cleaning, pulse cleaning and other methods. High pressure water jet cleaning uses high-pressure water flow to impact the dirt inside the mold waterway and flush it clean; Pulse cleaning generates strong impact force through pulsed water flow or air pressure fluctuations to remove stubborn dirt.