Application of Ultrasonic Cleaning Machine

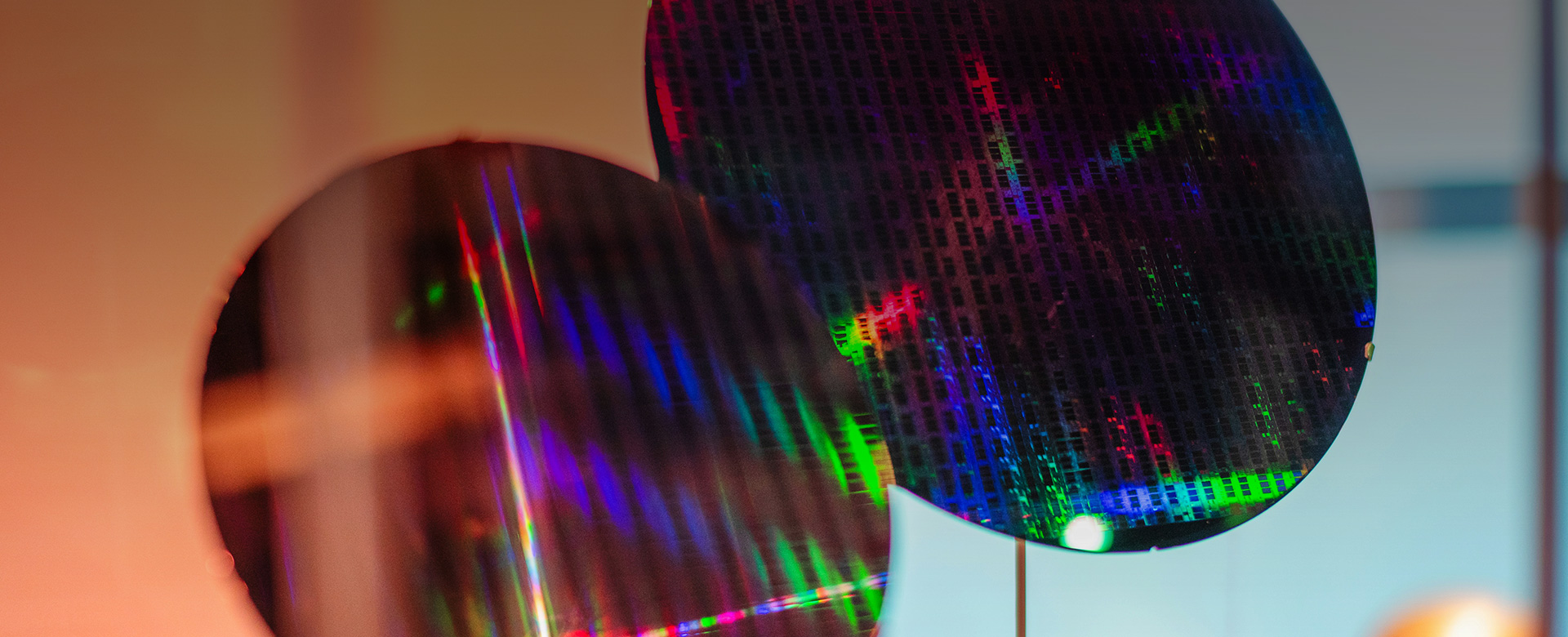

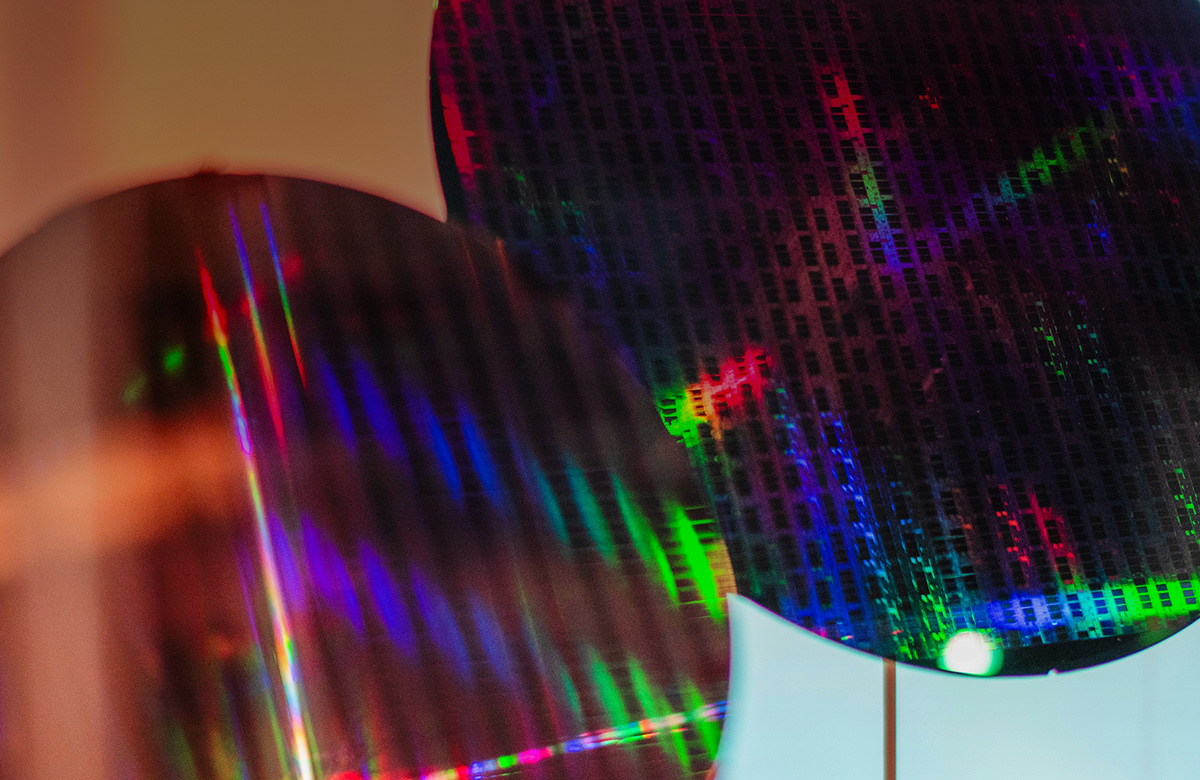

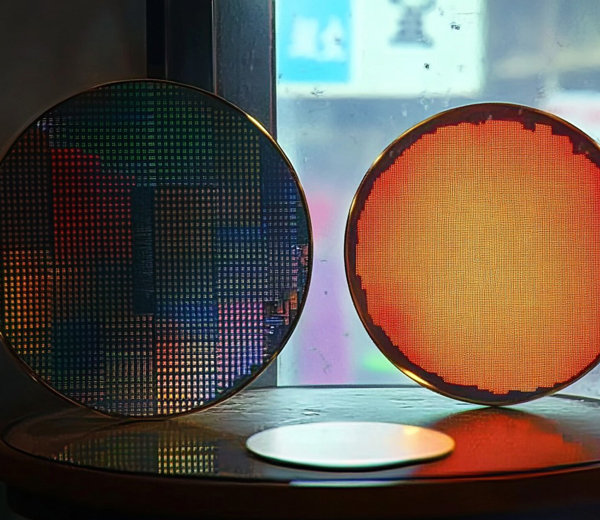

Ultrasonic cleaning machines have become an ideal choice in the semiconductor manufacturing field due to their unique cleaning principles and advantages.

Removing surface pollutants: Ultrasonic cleaning machines can quickly and thoroughly remove pollutants such as grease, particles, and dust from the surface of semiconductor materials through high-frequency vibration and the power of tiny bubble explosions, ensuring the purity of semiconductor materials and improving the performance and reliability of devices.

Cleaning microstructures: Common microstructures in semiconductor devices, such as micropores, microchannels, microcircuits, etc., are often difficult to thoroughly clean using traditional cleaning methods. Ultrasonic cleaning machines can eliminate dirt and particles from these microstructures through the transmission of vibration waves and the penetration of liquids, ensuring the cleanliness and good electrical performance of the structure.

Removing surface pollutants: Ultrasonic cleaning machines can quickly and thoroughly remove pollutants such as grease, particles, and dust from the surface of semiconductor materials through high-frequency vibration and the power of tiny bubble explosions, ensuring the purity of semiconductor materials and improving the performance and reliability of devices.

Cleaning microstructures: Common microstructures in semiconductor devices, such as micropores, microchannels, microcircuits, etc., are often difficult to thoroughly clean using traditional cleaning methods. Ultrasonic cleaning machines can eliminate dirt and particles from these microstructures through the transmission of vibration waves and the penetration of liquids, ensuring the cleanliness and good electrical performance of the structure.