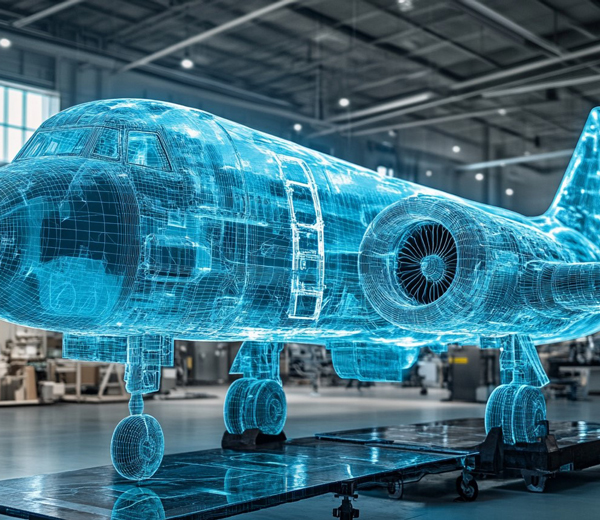

Application Examples

Cleaning of aircraft engine components: The cleaning machine can thoroughly clean the internal and external components of the engine, removing grease, carbides, debris, and other pollutants. The cleaned components can provide better thermal conductivity and aerodynamic performance, reducing the risk of failure and damage.

Cleaning of aircraft hydraulic components: The cleaning machine can thoroughly clean the internal and external surfaces of hydraulic components, removing grease, oxides, and other pollutants. The cleaned hydraulic components can provide better sealing performance and smooth movement.

Cleaning of aviation electronic components: The cleaning machine can effectively clean the surface and interior of electronic components, removing dust, grease, oxides, and other pollutants. The cleaned electronic devices can provide better conductivity and heat dissipation performance.

Cleaning of aircraft hydraulic components: The cleaning machine can thoroughly clean the internal and external surfaces of hydraulic components, removing grease, oxides, and other pollutants. The cleaned hydraulic components can provide better sealing performance and smooth movement.

Cleaning of aviation electronic components: The cleaning machine can effectively clean the surface and interior of electronic components, removing dust, grease, oxides, and other pollutants. The cleaned electronic devices can provide better conductivity and heat dissipation performance.